Cajo Technologies has provided metal industry players with smart and effective solutions for enabling functional traceability and product markings with sustainable marking solutions. In today´s metal fabrication and manufacturing environment, one of the big trends is automation. Cajo’s intelligent solutions support this trend through standard interfaces.

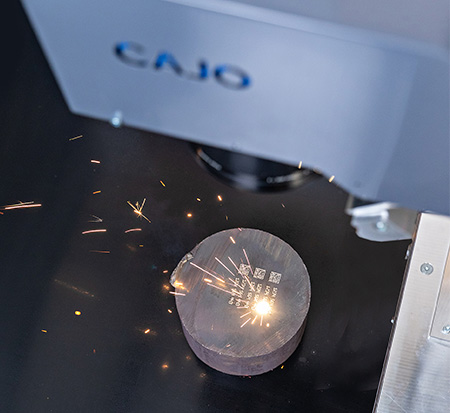

Marking on the fly is a typical requirement within the metal industry production environment. Often there are many things to consider due to facts like harsh environment, high temperatures, unclean environment, etc. There is a great demand for permanent and visible markings for securing internal and external traceability.

We are familiar with the challenges and can find solutions together with customers. We provide superior application support based on our experience with industry-leading companies such as Outokumpu and Tata Steel.

Choose Cajo for intelligent product marking.